Pile foundations support construction by transferring structure loads to deeper, stable soil or rock layers, crucial for stability. They come in various types, including concrete, steel, and timber piles, each with specific advantages depending on the project’s needs.

Moreover, piles are installed through methods such as driving, drilling, or screwing into the ground. The choice of pile type and installation method depends on factors like soil conditions, site constraints, and structural requirements.

Well-designed and installed pile foundations ensure stability and durability for buildings, bridges, and structures, making them crucial in construction worldwide.

What Are Pile Foundations?

Pile foundations are like sturdy support pillars for buildings, but they’re deep down in the ground. They’re long and slim, usually made of strong materials like steel or reinforced concrete, sometimes even timber. When we say a foundation is ‘piled’, it means it’s much deeper than it is wide, according to Atkinson in 2007.

These foundations come in handy when buildings need extra support. They help shift the weight from the building onto more solid ground deep underground, away from weaker or softer soil near the surface.

This way, they make the foundation stronger and more stable, especially against sideways forces. Pile foundations are often used for big buildings and in places where the ground isn’t strong enough to keep the building from sinking too much.

What Are The Types Of Pile Foundations By Function?

Pile foundation construction encompasses various types, each tailored to specific soil conditions and project requirements:

Sheet Piles

Sheet piles are primarily utilized to provide lateral support, resisting pressures from loose soil and water flow. They are commonly employed for the construction of retaining walls, cofferdams, trench sheeting, and shore protection, rather than offering vertical support to structures. Sheet piles serve various purposes:

- Construction of retaining walls

- Protection against riverbank erosion

- Retaining loose soil around foundation trenches

- Isolation of foundation from adjacent soils

- Confinement of soil to increase bearing capacity

Load-Bearing Piles

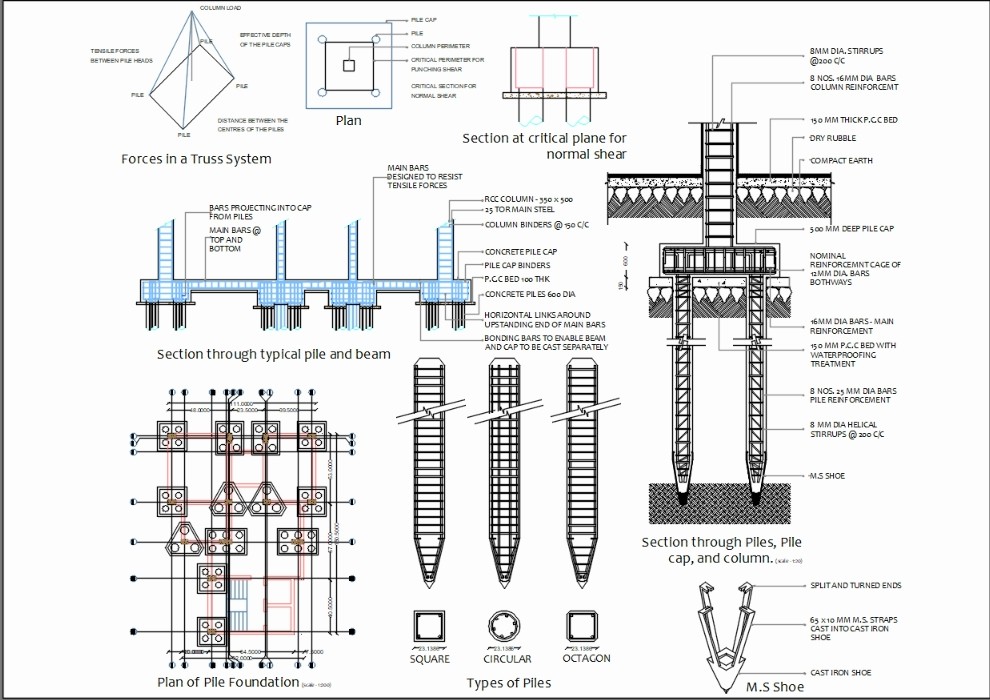

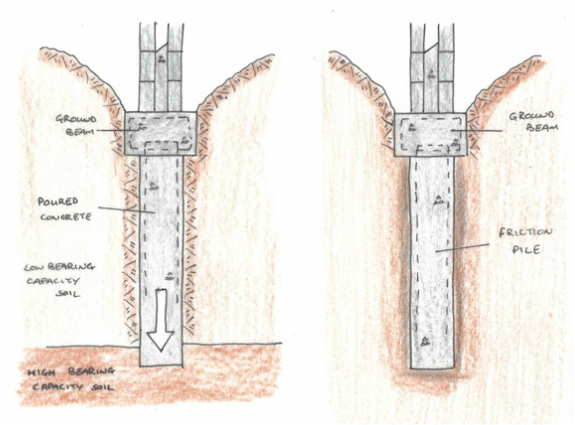

Load-bearing pile foundations are designed to transfer vertical loads from structures to the soil, transmitting them through poor supporting soil onto a capable bearing layer. Two main types of load-bearing piles are end-bearing piles and friction piles.

End-Bearing Piles

End-bearing piles transfer loads through their lower tip, resting on a strong layer of soil or rock. The total capacity of an end-bearing pile is calculated by multiplying the area of the pile tip by the bearing capacity of the soil at that depth.

Friction Piles

Friction piles transfer loads through frictional force between the pile surface and the surrounding soil, such as stiff clay or sandy soil. Friction can be developed along the entire length of the pile or a specific length, depending on soil strata.

The capacity of a friction pile is determined by the pile’s surface area multiplied by the safe friction force developed per unit area.

Soil Compactor Piles

Soil compactor piles differ from other types as they do not directly carry loads. Instead, they are driven at close intervals to compact the soil, thereby increasing its bearing capacity. This method enhances soil stability and reduces settlement risks.

Bored Piles

Bored piles, also known as replacement piles, involve excavating a hole into which the pile is poured in situ. Primarily used to create friction piles in cohesive subsoils and for pile foundations near existing structures.

Further, preferred in urban settings due to minimal noise and vibration, suitability for tight spaces, low risk of heave, and adjustability in length.

Driven Piles

Driven piles are installed by driving, jacking, vibrating, or screwing them into the ground, displacing the surrounding soil. They stabilize soft, compressible soils and can densify loose soil, making them valuable for offshore applications.

Then, concrete or steel casing, either permanent or temporary, is driven directly into the ground. Fabricated off-site from materials such as wood, concrete, or steel before being transported to the site.

Screw Piles

Screw piles feature a helix near the pile toe, allowing them to be twisted or screwed into the ground, akin to screwing into wood. They offer a convenient method of foundation installation, particularly in areas where soil conditions may pose challenges for traditional pile-driving methods.

Micropiles

They also known as mini piles, are employed in scenarios where access is restricted, such as underpinning structures affected by settlement. They can be either driven or screwed into place, providing stability and support in situations where conventional piles may not be feasible.

Pile Walls

Pile walls serve as both permanent and temporary retaining structures. They are constructed by arranging piles directly adjacent to one another. This method involves closely spaced contiguous or interlocking secant pile walls, with configurations based on secondary intermediate pile composition.

Geothermal Piles

Geothermal piles integrate pile foundations with closed-loop ground-source heat pump systems. These piles not only provide structural support but also act as a heat source and sink.

By utilizing the thermal mass of the ground, geothermal piles enable buildings to store excess heat generated by cooling systems. This heat can then be utilized for warming during colder seasons.

Contiguous Piles

Contiguous piles, as defined by Groynes in coastal engineering, involve cast-in-place concrete piles that are placed immediately adjacent to or touching each other. This method is sometimes utilized for plank piles and serves various applications in coastal engineering projects.

What Are The Types Of Piles Based On Materials And Construction?

Types of Piles Based on Materials and Construction Method.

Timber Piles

Timber piles are utilized in submerged conditions and typically endure for around 30 years. They’re available in rectangular or circular shapes, with diameters from 12 to 16 inches, and typically 20 times their top width in length.

Designed to handle loads of 15 to 20 tons, fish plates can be attached to their sides for added strength.

Advantages

- Regularly available in standard sizes.

- Economical and easy to install.

- Low risk of damage.

- Can be cut to desired lengths and easily removed if necessary.

Disadvantages

- Longer lengths may not always be available.

- Short piles can be challenging to keep straight.

- Difficult to drive in very hard soil.

- Splicing of timber piles is complex.

- Not suitable for use as end-bearing piles; require special treatment for durability.

Pre-cast Concrete Piles

Pre-cast concrete piles are cast horizontally in a bed for rectangular shapes or vertically for circular shapes. Reinforced with steel to prevent breakage, they undergo curing for 21 to 28 days after casting.

Advantages

- Highly resistant to chemical and biological damage.

- High strength and controllable quality.

- Easy to drive if pre-cast, can be driven underwater.

- Immediate loading capability after installation.

Disadvantages

- Difficult to adjust the length after casting.

- Heavy and expensive equipment is required for driving.

- Not readily available for purchase, potentially causing project delays.

- Susceptible to breakage or damage during handling and installation.

Cast-in-Place Concrete Piles

Cast-in-place concrete piles are formed by depositing freshly mixed concrete into bored holes or metallic shells driven into the ground.

Advantages

- Lightweight shells for easy handling.

- Length can be easily adjusted.

- Can be assembled on-site.

- No risk of breakage during installation.

- Additional piles can be easily provided if needed.

Disadvantages

- Requires careful supervision and quality control during installation.

- Needs ample on-site space for material storage.

- Challenging to construct in areas with heavy underground water flow.

- Bottom of pile may not be symmetrical.

- Unreinforced and uncased piles may fail in tension.

Steel Piles

Steel piles, available as I-sections or hollow pipes filled with concrete, are easy to drive due to their small sectional area and are commonly used as end-bearing piles.

Advantages

- Easy installation and splicing.

- Can penetrate hard soil layers.

- Capable of carrying heavy loads.

Disadvantages

- Prone to corrosion.

- Possibility of deviation during driving.

- Relatively expensive compared to other types of piles.

Pile Installation Methods

Various methods are employed for installing piles, tailored to project needs and soil conditions. Below are some common pile installation techniques:

Impact Driving

This method harnesses the force generated by a drop or hydraulic hammer, which strikes a driving cap atop the pile. The impact energy is then transferred through the pile, facilitating its penetration into the ground.

Impact driving offers simplicity and effectiveness, particularly in dense soils. Hydraulic hammers, in particular, provide enhanced control and reduced noise compared to traditional air or diesel hammers.

Widely applicable for both retaining walls and structural support piles, impact driving remains a cornerstone of pile installation in many construction projects.

Vibrodriving

Vibrodriving involves attaching an oscillating driver to the pile’s head, inducing vibrations that reduce friction along the pile’s sides. This reduction in friction facilitates easier insertion of the pile into the ground.

By minimizing resistance during installation, vibrodriving is particularly effective in soils with high frictional properties. It also reduces the risk of pile damage during insertion. Commonly used for reducing pile installation resistance, vibrodriving is especially beneficial in cohesive soils where frictional forces pose significant challenges.

Pressing (Jacking)

Pressing methods employ hydraulic jacks to push piles into the ground, using adjacent piles or reaction frames for support. This gradual insertion minimizes noise and vibration, making it suitable for sensitive environments.

Further, the low-noise and low-vibration nature of pressing methods minimizes disruption to surrounding areas, making them ideal for urban or environmentally sensitive sites.

Pressing methods are preferred for sheet pile installation, controlling noise and vibration to lessen impacts on structures or ecosystems nearby.

Driving Assistance Methods

Involves directing a high-pressure water jet at the toe of the sheet pile to reduce friction during installation. This method is particularly useful in granular soils where frictional resistance is high.

Utilizes a continuous flight auger to penetrate the ground along the pile line before sheet pile installation. This creates a void, reducing resistance and facilitating easier pile insertion.

FAQ’s

What is the standard size of pile foundation?

In general, Continuous Flight Auger (CFA) piles are usually 0.3 to 0.9 meters in diameter with a length up to about 30 meters. Smaller diameter piles, typically 0.3 to 0.5 meters, are commonly used in the United States, but larger diameter piles up to about 1.5 meters have also been utilized.

What is the principle of pile foundation?

A pile foundation involves inserting columns into the ground to transmit loads to a lower level of subsoil. Piles, typically long cylinders made of strong materials like concrete, are pushed into the ground to provide steady support for structures built on top of them.

Final Words

Pile foundations play a vital role in ensuring the stability and durability of buildings and other structures. By transferring loads to deeper, more stable soil or rock layers, they provide essential support, especially in challenging soil conditions.

With various types and installation methods available, pile foundations offer flexibility to suit different project needs. Whether it’s concrete, steel, or timber piles, choosing the right type and method ensures a strong foundation for construction projects.

Overall, pile foundations contribute significantly to the safety and longevity of structures, making them indispensable in the world of construction.